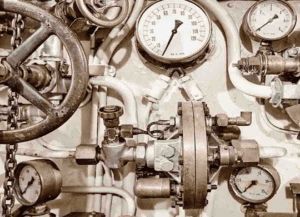

QA QC Instrumentation Course

Learn about the QA QC Instrumentation Courses get employed Instrumentation sector. This is a course in the Instrumentation domain.

- 24 weeks long course | Online and Offline

- Learn from leading experts in the industry

- Project based learning with 4 industry level projects that learners can showcase on LinkedIn.

- Learn Key Tools & Technologies in Automation